How Rubber Keypads improve safety and performance in industrial equipment

Discovering the Manufacturing Process Behind Rubber Keypads and Their Importance in Modern Gadgets

Rubber keypads are crucial in the capability of modern-day tools. Their manufacturing procedure includes cautious choice of products and exact methods. Keypads are developed to improve customer interaction while ensuring longevity and dependability. Comprehending just how these components are made exposes their importance throughout various applications. What aspects add to their effectiveness, and just how do these components affect user experience? The responses may reshape understandings of this everyday modern technology.

Overview of Rubber Keypads and Their Applications

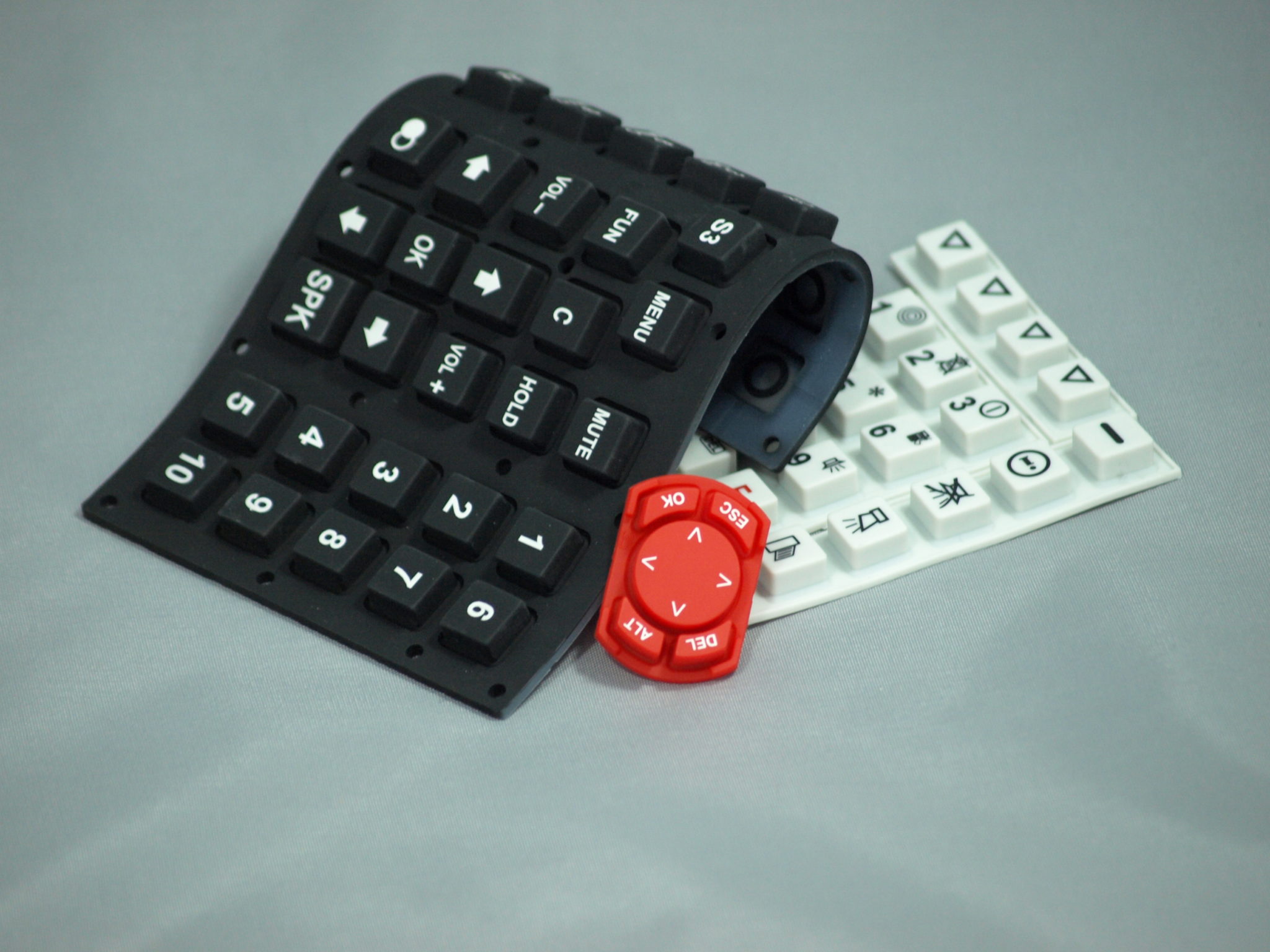

Rubber keypads are versatile components widely used in numerous digital devices, ranging from consumer electronics to commercial equipment. Their style permits a responsive feedback, making them an optimal selection for applications requiring user interaction. Generally found in products such as push-button controls, calculators, and medical tools, rubber keypads facilitate simplicity of usage and availability.

In commercial settings, they offer vital functions in equipment and control panels, where durability and resistance to environmental elements are essential. The non-slip surface area improves hold, promoting integrity sought after conditions. Additionally, their lightweight nature and personalized forms make it possible for makers to produce tailored solutions that fit certain requirements. With developments in modern technology, rubber keypads remain to progress, integrating features like backlighting and boosted sensitivity. In general, their adaptability and useful benefits add considerably to the performance of different tools across numerous industries.

Materials Utilized in Rubber Keypad Production

Keypad producing depends on an option of products that improve both functionality and toughness. The main product utilized in the manufacturing of rubber keypads is silicone rubber, understood for its outstanding durability and flexibility. This material permits keypads to withstand repeated pushing without losing form or efficiency. Additionally, polycarbonate elastomers (TPE) are frequently used because of their convenience of molding and capacity to give a soft-touch feeling.

Tinting representatives, such as pigments, are incorporated to ensure dynamic, lasting shades that improve aesthetic charm. Ingredients like anti-UV representatives and flame resistants may be mixed into the rubber to boost weather resistance and safety compliance. The choice of materials straight influences the keypad's responsive response, durability, and general performance in different gadgets. Ultimately, the cautious selection of these elements is essential for the production of high-quality rubber keypads that meet customer and sector demands.

The Layout Process of Rubber Keypads

When creating rubber keypads, the layout procedure plays a necessary role in establishing performance and customer experience. Designers begin by specifying the keypad's meant usage, considering elements such as the device it will certainly go along with and the target user demographic. This preliminary stage includes sketching formats that prioritize ergonomic facets, guaranteeing the tricks are easily available and appropriately spaced.

Next, designers concentrate on the tactile responses wanted from the keypads, which influences the choice of materials and key shapes. Prototyping is vital in this stage, allowing designers to check numerous designs for comfort and responsiveness.

Manufacturing Techniques for Rubber Keypads

The production process for rubber keypads involves a collection of specific methods that assure top quality and functionality. Liquid silicone rubber (LSR) is commonly used due to its durability and adaptability. The process starts with blending the raw materials, consisting of silicone, colorants, and treating agents. This mixture is then infused right into mold and mildews developed to shape the keypads accurately.

Following injection, the molded keypads go through treating, a home heating process that solidifies the product (Rubber Keypads). This is commonly carried out in a press, ensuring the keypads achieve the desired hardness and durability

Quality Assurance Actions in Production

To ensure that rubber keypads satisfy high requirements of quality and performance, extensive quality assurance actions are carried out throughout the manufacturing procedure. These procedures begin with resources assessment, guaranteeing that just the highest-grade elastomers are utilized. During the manufacturing stage, drivers conduct normal checks to check parameters such as temperature, pressure, and mixing times, critical for attaining consistent item top quality.

Post-production, each set of keypads goes through complete testing, consisting of responsive feedback analyses and resilience tests to evaluate performance under different problems. Visual assessments are also conducted to recognize any type of flaws, such as bubbles or disparities in texture. In addition, conformity with industry requirements is verified, ensuring that the keypads meet security and functionality standards.

The Role of Innovation in Keypad Advancement

Technology plays an essential function in the advancement of rubber keypads by enabling advanced manufacturing strategies that improve accuracy and effectiveness. Furthermore, cutting-edge material option permits enhanced durability and responsiveness in keypad efficiency. These innovations not just streamline production yet additionally boost the total top quality of the final product.

Advanced Manufacturing Techniques

Advancements in production strategies transform the manufacturing of rubber keypads, improving both performance and precision. Technologies such as injection molding and 3D printing have changed conventional processes, allowing makers to produce intricate layouts with reduced waste and enhanced turn-around times. Automation plays an important duty in this evolution, improving setting up lines and lessening human mistake. Furthermore, computer-aided layout (CAD) software application permits intricate customization, guaranteeing that keypads satisfy specific customer needs. Quality control actions have actually likewise advanced, incorporating real-time tracking systems that identify defects early in the manufacturing cycle. These developments not just improve the sturdiness and functionality of rubber keypads but additionally support the growing need for tailored services in different industries, from consumer electronics to automotive applications.

Innovative Material Choice

The evolution of manufacturing methods has led the way for ingenious product choice in rubber keypad growth. Advancements in polymer scientific research have introduced materials that enhance durability, adaptability, and responsive responses. Producers now use thermoplastic elastomers (TPE) and silicone compounds, which give remarkable resistance to use and ecological variables. These materials enable the creation of keypads that can sustain long term usage while keeping visual appeal. In addition, the combination of ingredients and layers see here improves functionality, such as enhancing grasp and reducing rubbing. The option of products is essential, as it directly affects the efficiency and long life of keypads in various devices, from consumer electronics to industrial devices. This ingenious approach remains to shape the future of keypad design and functionality.

The Influence of Rubber Keypads on User Experience

Rubber keypads considerably affect individual experience with their enhanced tactile response, which permits even more accurate communication. In addition, their durability and durability add to constant performance in time, decreasing the requirement for frequent replacements. This mix of attributes makes rubber keypads a preferred selection in various applications, inevitably impacting user contentment.

Improved Tactile Feedback

Enhancing tactile response greatly influences customer experience, especially in gadgets that count on keypads for interaction. Rubber keypads give a special combination of gentleness and durability, permitting users to feel distinct feedback with each press. This feedback enhances a sense of control and precision, crucial in applications varying from smart devices to industrial equipment. Customers usually report greater complete satisfaction and effectiveness when interacting with gadgets that include properly designed rubber keypads, as they facilitate quicker and much more exact input. Additionally, the ergonomic layout of these keypads can lower finger tiredness, promoting longer use periods without discomfort. Overall, the improved tactile reaction given by rubber keypads significantly contributes to an extra user-friendly and pleasurable user experience in modern-day technology.

Sturdiness and Longevity

A crucial facet of customer experience with rubber keypads exists in their sturdiness and longevity. These keypads are made to endure comprehensive use, resisting wear and tear that typically influences various other materials. The robust nature of rubber warranties that keypads keep their performance and appearance with time, which is essential for gadgets regularly utilized in different environments. Individuals take advantage of the dependability of rubber keypads, as they can withstand direct exposure to temperature, wetness, and dust variations without wearing away. This durability not just boosts individual fulfillment but additionally lowers the demand for frequent substitutes, eventually adding to cost-effectiveness for suppliers. Basically, the durability of rubber keypads substantially affects the total efficiency and user experience in modern-day devices.

Often Asked Questions

For How Long Do Rubber Keypads Typically Last in Devices?

Rubber keypads commonly last between 5 to ten years, depending on usage, ecological factors, and high quality of materials made use of (Rubber Keypads). Normal deterioration can reduce their life-span, influencing performance and individual experience with time

Can Rubber Keypads Be Personalized for Details Applications?

Rubber keypads can indeed be customized more helpful hints for certain applications, permitting modifications in dimension, color, structure, and shape. This adaptability makes it possible for producers to produce tailored remedies that meet varied user demands and improve functionality in different devices.

Are Rubber Keypads Eco-friendly?

Rubber keypads are frequently ruled out eco pleasant because of their petroleum-based materials. Advancements in lasting manufacturing methods and the growth of bio-based choices are progressively enhancing their eco-friendly influence in numerous applications.

What Are Typical Problems Dealt With During Rubber Keypad Manufacturing?

Common issues dealt with throughout rubber keypad manufacturing include irregular worldly top quality, mold flaws, improper healing times, attachment failures, and difficulties in accomplishing specific tactile feedback. These issues can lead to lowered product performance and customer discontentment.

Just How Do Rubber Keypads Contrast to Various Other Types of Key Switches?

Rubber keypads use a softer feel and quieter procedure contrasted to mechanical buttons, which supply tactile feedback. Nevertheless, rubber keypads may wear faster and do not have the precision that some users choose in high-performance applications.

The main material used in the manufacturing of rubber keypads is silicone rubber, known for its exceptional durability and flexibility. When creating rubber keypads, the layout process plays a vital role in determining functionality and individual experience. Rubber keypads greatly influence customer experience through their enhanced tactile reaction, which enables for even more exact interaction. Customers usually report greater contentment and performance when engaging with gadgets that feature well-designed rubber keypads, as they assist in quicker and much more exact input. An essential aspect of customer experience visit site with rubber keypads exists in their longevity and long life.